China has completed the world’s first fully unmanned paving construction project

Unmanned construction drone swarms paved and rolled across a 157.79km stretch on the Beijing-HK Expressway, completing the world’s first fully unmanned road paving project

On the afternoon of the 27th of september, the paving project controller Hubei Communications Investment, the project general contractor China Railway 11th Bureau & the construction unit Liaoning Guotai Road and Bridge jointly completed the unmanned clustered intelligent paving and rolling operation on the large-width road surface. All of these groups are state owned.

The machinery was provided by Sany Group, a mixed ownership firm, successfully completing the industry’s first unmanned paving construction demonstration on the largest width road surface and the largest scale, marking a new step in the level of intelligent construction of China’s highway construction.

High-speed surface construction has extremely high requirements for rolling equipment and operation technology. This time, multiple Sany high-end unmanned road equipment were used, including a 20-meter wide paver, six 13-ton double steel wheel rollers, and three 30-ton rubber wheel rollers. The 1+3+3+3 lineup formed a huge construction fleet, and the standardized operation of the fleet was achieved by relying on intelligent scheduling algorithms.

Beidou’s centimeter-level high-precision positioning system and the self-built low-latency communication network implement real-time optimal path planning for the fleet in strict accordance with the rolling process requirements, achieving “close following and slow rolling”, avoiding missed pressure or under-pressure, and ensured rolling quality.

What is particularly striking is that the SAP200C-10 large-width unmanned paver deployed by Sany this time achieved one-time paving with a paving width of 19.25 meters in actual construction, which is the first time in the field of domestic and even international road construction.

The SAP200C-10 paver is a construction tool designed for wide-width asphalt construction on high-speed 2-lane to 4-lane roads. In this project, the SAP200C-10 large-width paver not only greatly improved construction efficiency and reduced the number of joints, but also effectively improved the flatness and durability of the road surface

The Sany drone swarm used in this project, through high-precision path tracking algorithms and self-developed fusion high-precision self-sensing positioning systems, can accurately identify and locate the curbstones, truly achieving “0” edge-to-edge operation. No small roller is needed for edge trimming, and the road surface is formed in one step, greatly improving the work efficiency and quality.

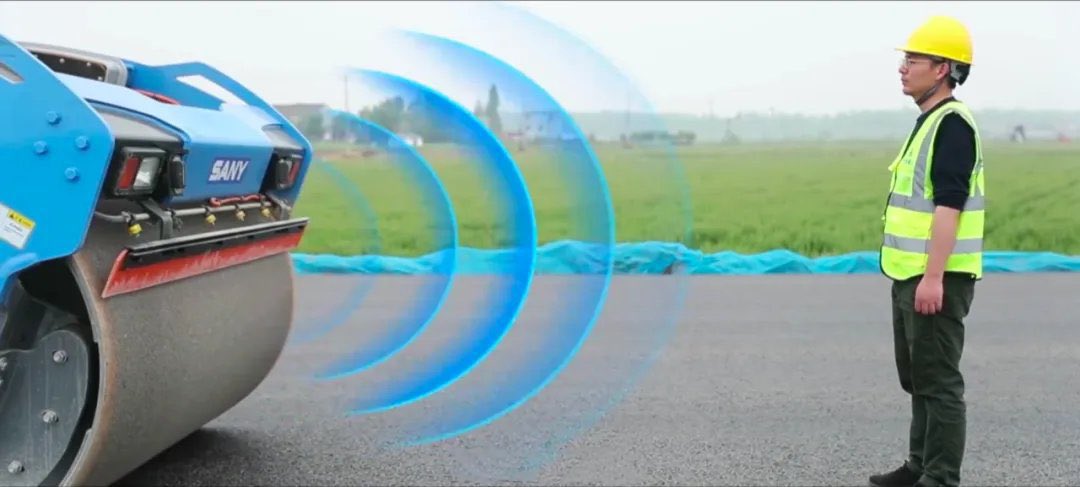

Construction site safety is a top priority, and safety is even more important for drone swarms. The unmanned spreading machine swarm obtains the full operating status of all equipment and surrounding obstacle information in real time.

The drones are equipped with multiple redundant safety protection strategies such as collaborative safety, electronic fences, emergency stop systems, perception and obstacle avoidance systems. According to the risk level, the equipment can be decelerated, paused, and emergency stopped in real time to ensure operation safety

This attempt is undoubtedly a major breakthrough in traditional paving technology, marking a double leap in China’s road construction technology in terms of width and efficiency

Source: 大项目,大宽度,大规模!三一无人机群登陆京港澳高速改扩建工程 – 中国路面机械网